When you turn on the faucet to wash your hands or take a shower, do you ever wonder how the water gets to your house? Water flows through factory-made pipes. Making these pipes is one key piece of the puzzle in delivering water to homes and buildings. The text takes us through producing pipes on SBKJ SPIRAL TUBEFORMER machines. It makes the whole process fast and convenient, and this is where these machines come in.

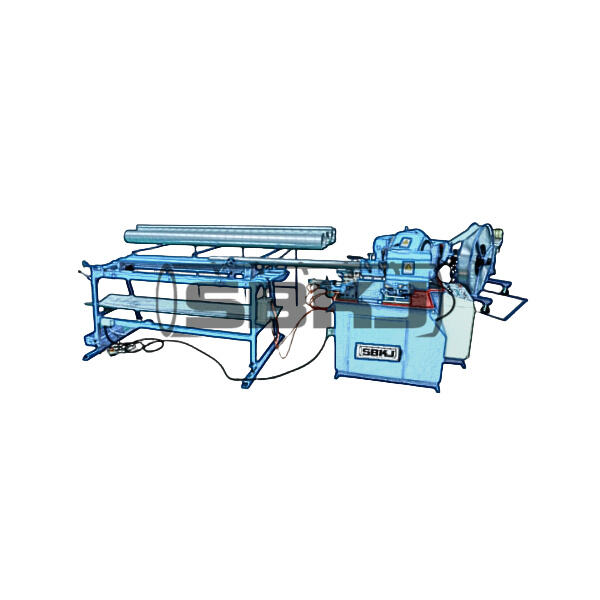

The SBKJ SPIRAL TUBEFORMER machines are used to produce pipes in a fast and simple manner. These ribbed spiral pipe producing machine machines do their thing all by themselves, which means they don’t need people to assist them while they work. First the machine grabs a large roll of metal — like a giant ribbon — and squeezes it through a series of rollers. These rollers are used in shaping the metal. The metal then passes through rollers that shape the metal into a pipe. After that, they weld the ends of the pipe together. Welding is where you heat the metal until it fits perfectly. Then, the machine snips the pipe to the required length, and the pipe is good to go for homes, buildings, and all kinds of other places.

SBKJ SPIRAL TUBEFORMER Machines keeps the great speed to provide good quality pipes. As for quality, the pipes are very well made and safe to use. These machines are extremely accurate, meaning the pipes are all the same shape and size. This Ribbed spiral pipe producting machine matters because, if the pipes are not the same size, water and other liquids might not move through them properly. Pipes that help water go from one place to the other are built in the right sizes. Since fewer people are doing this work, and it is actually done with machines, it has a less opportunity for error. It means the rights are wronged, sorry, wronged, sorry, wronged.

When you are making pipes, you need to ensure you have a very high level of safety. It is important that the machines are equipped with special safety features to ensure the well being of those that operate the SBKJ SPIRAL TUBEFORMER machines These features may include sensors that detect when someone is standing too close to the machine. If a worker comes too close, the machine may slow down or stop. There are also emergency stop buttons that will immediately turn off the machine if there is an error. It covers everyone in the event of an accident, helping to keep all parties involved safe. Other safety features include protective shields that cover hazardous moving parts so that workers do not get injured. Employees also undergo extensive training to learn how to safely run the machines and follow crucial safety regulations.

New Technologies for Making Pipes

With advances in technology, the processes used to produce the pipe components are also evolving. In order to meet human beings' needs today, SBKJ SPIRAL TUBEFORMER is constantly improving their machines. For instance, Spiral Duct they may employ new, longer-lasting materials that do not rust or break as easily. Rust is what happens when metal gets wet, goes bad. A new set of materials helps avoid this. They can also create features on the machines that assist them in performing better. These improvements might involve new controls for the machines or even new tools that help make those pipes even stronger. This means that by leveraging the latest technology and keeping up with the latest news, SBKJ SPIRAL TUBEFORMER can serve their customers with the best products and services.

We offer a dedicated customer service rep for each customer along with a fixed After-Sales Service Hotline and a WeChat Group that is dedicated to after-sales. Online, you can Pipe Production Line us easily. We can quickly solve your issues using the Internet. SBKJ equipment is protected by a lifetime maintenance plan and warranty for one year.

SBKJ offers Pipe Production Line service. You can choose to remove the SBKJ logo from your device, or request a custom device color. The language that the software uses can also be selected provided that you can provide translations to minor languages. We can also customize your equipment depending on your specific production requirements.

SBKJ Group has its Pipe Production Line in the Yangtze River Delta near Shanghai, China. SBKJ is a manufacturer of spiral tubeformer with more than 30 years of experience. SBKJ spiral tubes can be manufactured to meet DIN, BS Euroorm and Smacna standards. Our customers are from more than 60 countries around the globe.

SBKJ has been a pioneer in the spiral duct manufacturing industry for years. They have a number of patents such as Flying silitter Flying crinnper, and Flying teeter. SBKJ's research and development forms the basis of the tubeformers we use to automate our work, which can produce Pipe Production Line of high quality at low costs.