We must construct roads, bridges, tunnels, and special pipes that are as much as this level. These are culvert pipes that keep water, people and things flowing as needed. Without these pipes, rainwater would inundate on our streets and transportation would become nightmarish. A machine was developed by SBKJ SPIRAL TUBEFORMER to quickly and efficiently manufacture these stout culvert pipes.

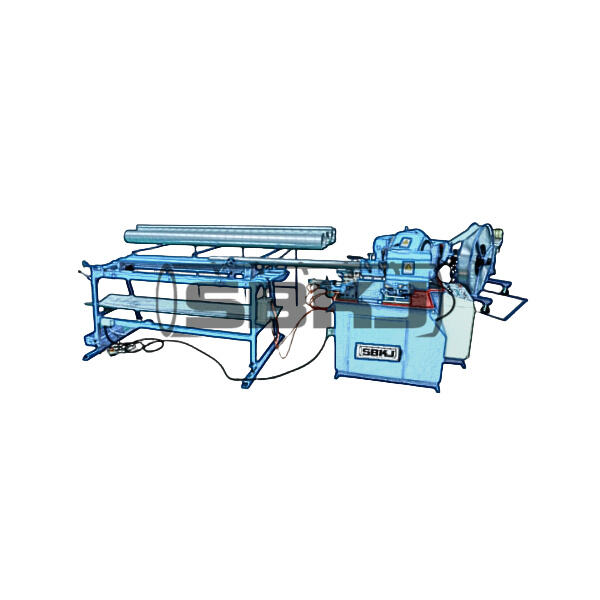

This awesome craft is called machine made of SBKJ SPIRAL TUBEFORMER. It is a quick and accurate way to manufacture pipes. They take metal coils and turn them into strong, reliable spiral pipes with a machine. Utilizing a high-tech system to ensure that every pipe is produced precisely as expected. This way the workers do not take much time in manufacturing the pipes and have more time in constructing the structures where they are required.

When the metal is mixed appropriately, the machine molds the pipes. It ensures each pipe is durable and comes in various sizes as per the requirement. These pipes are weatherproof and can stand heavy rain, snow etc. They also do not corrode, which is metal damage and are able to endure heavy loads from vehicles without breaking. This is especially important as it gives quality pipes that would not need repairing for many years.

Spiral pipe machine is highly versatile and has a wide range of applications in the construction industry. It can produce pipes for drainage systems to remove rainwater, stormwater management to avoid floods, and even underground tunnels. It is also helpful for building pipes in areas like underground mines and irrigation systems that help needy crops grow. SBKJ SPIRAL TUBEFORMER is capable to customize ISM tailored to suit the unique requirements of each project, which guarantees builders get exactly what they need.

Our SBKJ SPIRAL TUBEFORMER machine is an efficient and eco-friendly solution. This gimmicks metal coils that are fully reusable — meaning they can be recycled endlessly instead of ending up in the trash. Since the machine essentially makes pipes — as opposed to cutting them from a larger piece of material — it also creates less waste and uses less energy in the process. It is a meaningful step in the direction of sustainability. It manufactures quality pipes which are not only durable but also very strong and need far less repair, or replacement over time, saving much time as well as resources too.