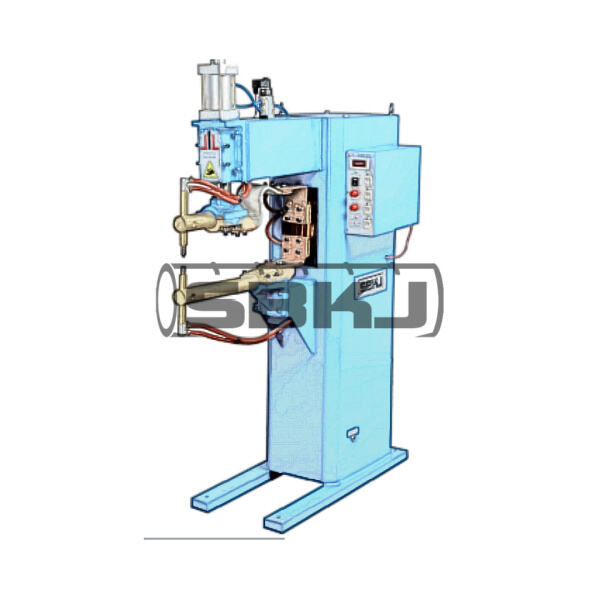

The Spotwelder of the SBKJ SPIRAL TUBEFORMER The SBKJ-SPIRAL-TUBE-FORMER is a powerful and globally unique tool. It assists in holding metal parts together in a safe and practical manner. Spot Welder — By its name, the spot welder works via small amounts of electricity that are turned into heat. The heat generated is so intense that it can melt the metal components. The molten metal will solidify upon cooling and forms a permanent bond between the two components. The metal link thus produced is not only strong but also robust. Spot Welders are used all over, from car factories to construction sites to airplane assembly plants. This tool allows you to ensure that the entire assembly is fitted properly and secured—safely.

The 1602 forming head with which it joins is really careful and precise. It is capable of forming a solid attachment without damaging the metal parts. With a proper Spot Welder, an important factor is that the person who operates it should be well trained to make sure you get the best output of the weld. The operator needs to remember how much pressure to use and for how long to hold the spot welder in place. If they get it precisely correct, they could execute an ideal weld. Other settings are available on the Spot Welder. These options enable it to perform across multiple metal types and thicknesses which, adds a significant versatility for various series of tasks.

A Spot Welder works by means of two pieces known as electrodes. These electrodes are firmly pressed against the metal pieces to be joined. As this electric current passes through these electrodes, the result is heating that heats the metal up to its melting point. The heating process takes only a few seconds. This rapid heating is critical so that the metal does not overheat or distort. The molten metal resulting from this something or the other heat is then joined together and cools quickly. As it cools it sets into a very strong bond between the two metal pieces.

There are plenty of advantages to using a Spot Welder over other methods of welding. The major factor is it establishes highly robust joins. This can be very critical for the industries that are concerned with safety such as airplane making. The parts can resist together and do not break apart when a strong weld is present. The spot welder is also exceptionally fast. Unlike other welding methods, it can form a weld in second. Speed is key when it comes to getting many parts attached together in a timely manner. The Spot Welder is also very accurate, which is another great thing about it. You can use it for tiny some joins in a small region which helps you out on so many projects.

Spot Welder in the manufacturing & factories sector. You use it quite a bit in welding pieces of metal together to form larger structures. Spot Welder: Used to join the metal panels of a car in car manufacturing as an example. These integrations lead to a strong and robust car body which can withstand various situations. Construction as well involves the use of Spot Welder wherein metal beams have to be joined together and make up the structure of a building. This is a crucial stage in making sure that the strength and safety of a building.