What does Oval Roller mean? Oval duct machine: this type of machine is dedicated to producing oval ducts. The ducts are integral to HVAC heating, ventilation and air conditioning systems that we've come to know. These ducts play a vital role in circulating warm or cool air inside buildings and our homes. Oval ducts are similar to round in that they both have cross sectional shapes, however; a duct with an oval shape has one flat side and the other curved side. It is shaped like that, and this is one reason why it is really essential that an oval duct machine would have the ability to shape the steel in simply such a method.

A long time ago,! before we had a machine to make oval duct, it took forever to do because it was terribly laborious work. Everything had to be made by hand including using a hammer and a mold. This process was time consuming and needed heavy labourers. Can you imagine making each duct by hand! The shapes, at times, weren’t fitting perfectly since it was a tedious job and dragged on for quite some time due to the errors committed during the procedure.

Well, the oval duct machine has become one of the most important tools in the HVAC industry again thanks to a recent technology. It significantly speeds up and simplifies oval duct production. Using this machine, the workers can produce oval ducts of similar shape and size in lesser time. This conversion allows workers to complete their work faster and more economieally.

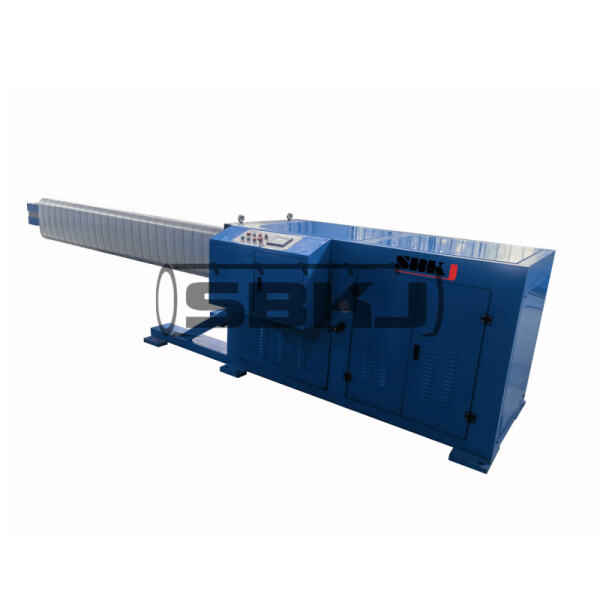

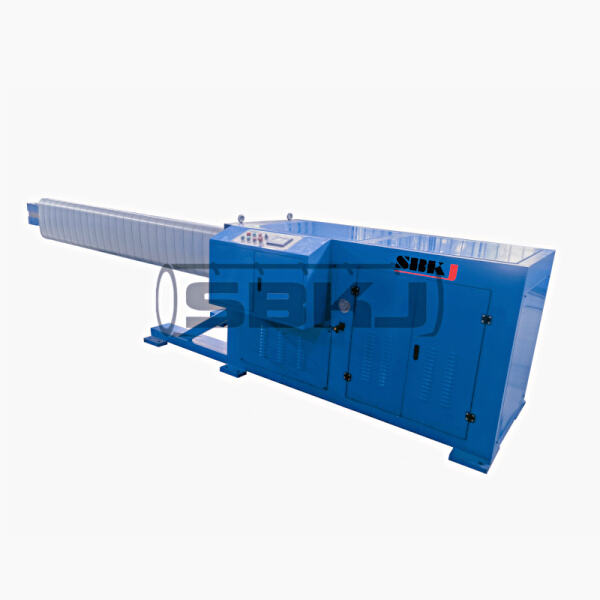

Oval duct machines have advanced high technology created perfect oval ducts which consist of a modern oval duct machine such as the SBKJ SPIRAL TUBEFORMER MEHLBERG flextube area, etc. They have intelligent controls that allow workers to preload the duct shape from a given design program into the machines. This allows workers to make each individual duct as required by using these controls.

Workers can also determine the thickness of the metal while making duct if a good oval duct machine is used. This means that the oval ducts could be more robust and durable, which is quite essential for HVAC systems. Moreover, these machines tend to be user-friendly so individuals with limited experience can produce quality oval duct. This accessibility is what more workers are capable of contributing to the process, and this makes it work even smoother.

With the constant evolution of HVAC, it follows that the duct making equipment must evolve as well. SBKJ SPIRAL TUBEFORMER is an innovative machine with the latest and most advanced design of oval duct machines, and it offers several improvements in the process of making ducts. These machines can for instance be couple with a laser cutter where metal sheets are cut to the appropriate shapes before actually being formed into ducts. It does add an extra step, but that makes it faster and more accurate.

In addition, machines from SBKJ SPIRAL TUBEFORMER can cater to different thickness and types of steel. This implies that it is highly adaptable given its ability to create oval ducts for different types of HVAC systems. These machines also ensure that nature is not exploited due to their energy-efficient design. By consuming less energy they help reduce the impact on our planet, so they are also a wise long-term choice.