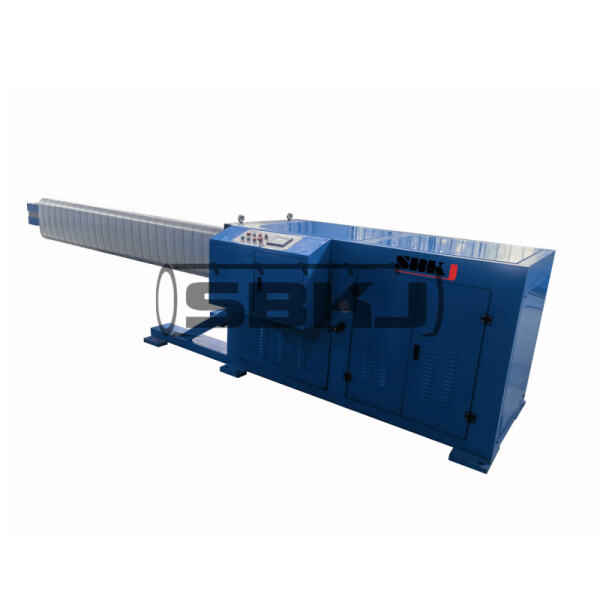

One of them is the Oval Roller that plays an important role in producing a lot of the items we use in our daily lives. The machine is special because it uses oval-shaped dies to form pipes. These pipe characteristics have extensive usage in various products. SBKJ SPIRAL TUBEFORMER is among the most popular manufacturers for such machines and many companies use it for manufacturing their products in multiple sectors.

A machine that converts flat sheets of metal or other material into an oval shape using rollers. These machines are sort of like taking a flat piece of dough and rolling it out so you turn the circle with adhesive into a more flat, round shape. They are made of high-quality materials and with careful design, aid in the exact shaping of the pipes. Since the pipes are so well made, they come out smooth and homogeneous, meaning they will have the same appearance every time.

Oval forming machines play a key role in several businesses due to the need for products used to produce engines, boilers, and much more machines. These machines are particularly useful in areas where precision and speed are required to manufacture things. Like if a company is wanting to create a production of oval pipes to assemble some facilities they need, then use machines like these because it makes things easy and much more accurate and faster.

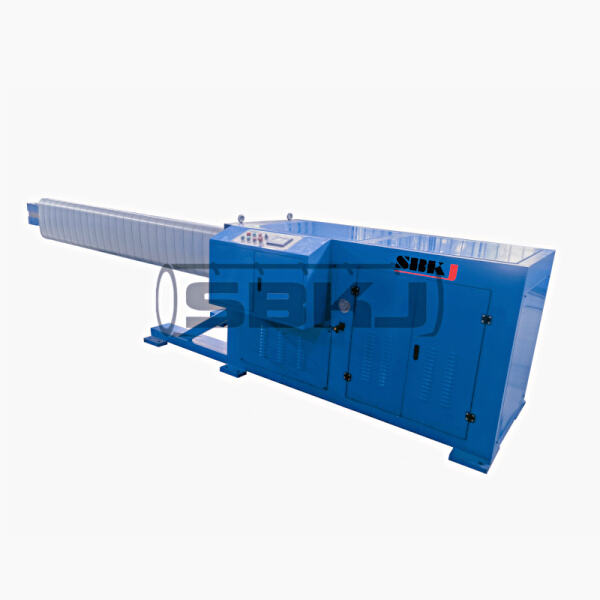

The advantage of an oval forming machine is that it creates consistently sized and shaped pipe each time. This consistency is vital so that the different components mesh together when they are used. This also makes it less wasteful, which is better for the environment and for saving money. They can also be configured to produce varying sizes and shapes of oval pipe with minimal changeover of components. This versatility is exactly why they are a big help for all sorts of projects.

Making oval pipes is laborious before the appearance of oval forming machines, creating ovum used to be a tough and time-consuming process. This had to be done by hand, so the pipes would not have uniform sizing or shaping. It might have conflicting issues while placing the pipes in other products. This means that making pipes like these used to be a lengthy process but with the enamel match now being done by an oval forming machines has sped the process up as well as having reformed and improved things. These days, these machines are able to work fast and conserve a good amount of money with more products manufactured simultaneously.