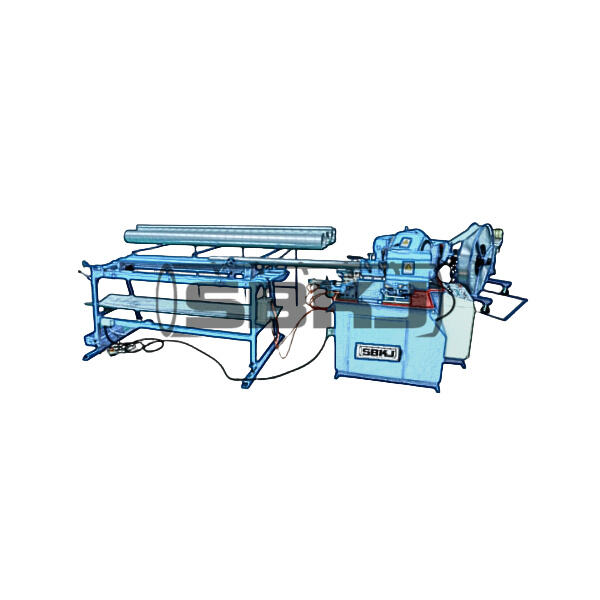

SBKJ SPIRAL TUBEFORMER machines are state-of-the-art spiral tube forming machines with extensive applications. The machines are specifically made to create the tubes exactly at the required dimension for their application. Which means that each and every tube is made with so much attention to detail ensuring that it is just right for what you want to use it for.

They utilize a process known as spiral tubeforming. By this, I mean that they take a flat metal strip and roll it into spirals. This method produces a robust and rich tube suitable for various uses. These tubes are durable and can be trusted and utilized in several industries varying from construction to HVAC systems.

SPIRAL TUBEFORMER machines of SBKJ are very effective spiral tube maker with high speed. Because they are able to manufacture tubes at a very quick pace, this makes them perfect for use in the HVAC industry that deals with heating, ventilation and air conditioning as well as other kinds of work that includes ductwork and ventilation systems.

And best of all, they are as easy to use as these machines get. They are equipped with easy, user-friendly control features that assist the workers in setting the machine and working efficiently without any hassle. This makes it so that even novices to this type of work are able to learn quickly and use the machines effectively. These machines are as simple to operate as learning the right way on how to do it and with a little practice; anybody can make an expert use of them.

SBKJ SPIRAL TUBEFORMER have intelligent systems which provide for customization of spiral tubes as per userδου with_inputs/outputs ranging between Oct 2023 Which means you can alter the tubes to suit and meet certain needs and specifications. So for example, you can use the right size, length and thickness of tube that you require to carry out a specific job.

The machines can also be set up to cut different types of spirals. These can be single pitches and double pitches, or even custom pitches that give the highest performance for particular applications. And in making the tubes more useful for whatever purpose they are being employed for, this flexibility means greater efficiency.

They are also easy to operate, and you can work efficiently on these machines. This is why they need very little time to set up and are ideal for both small-scale production as well as large-scale production runs. Fast production with these machines, they can do full batch or small number of tubes. They are also capable to handle various materials, allowing users more versatility in their production methods.