Have you ever wondered of how to make a spiral tube? It’s pretty interesting! Due to advancements in technology, the process of producing is still quicker and simpler than it used to be. So, in the case of producing spiral tubes if we talk about the types of techniques which could be used then one of the finest technique is through using Double Lock Seaming method. This technique is highly preferred as it provides strength and security to metal fixtures. In this Double Lock Seaming method, two sheets of metal are connected along the edges to further shape them into a spiral tube. These tubes have special double lock seam. The seam makes it more difficult for the tubes to pull apart, so they are strong and reliable for many uses.

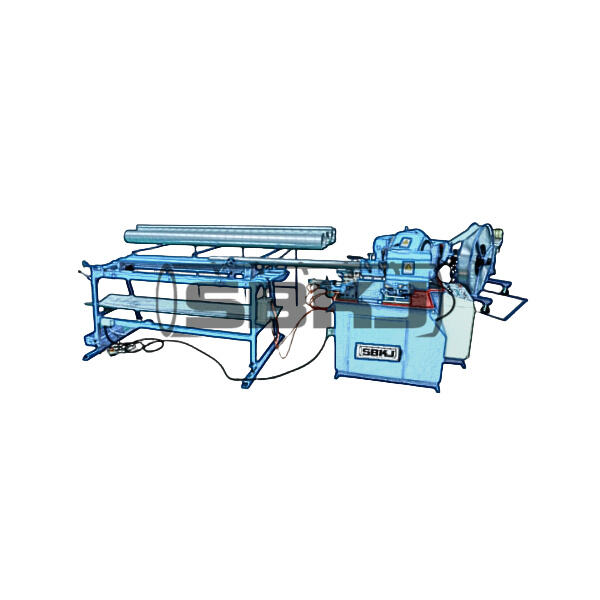

Conventional machines have made things crystal clear when it comes to spiral tubes. These tubes have to be made very accurately which also makes a good Tubeformer machine so necessary. For example, the SBKJ Spiral Tubeformer is a special purpose machine designed to produce spiral tubes using the double lock seaming process. One more remarkable part of this machine is that the automation in it does wonders, Automated process improves the accuracy and stability while making spiral for tubes. After years of experience, SBKJ has produced one of the best machines on the market today. Operators can specify very precise lengths and dimensions of the tubes desired with this machine, ensuring a perfect fit.

Double Lock seaming technique is an ingenious way to join two pieces of metal extremely securely. It forms a durable physical bond that can endure various directional forces like wind, or unlike directional forces as pressure. The double lock seaming is the favoured option for spiral tube manufacturing due to this robustness. However, with the SBKJ SPIRAL TUBEFORMER, it is even safer and more reliable. The machine produces completely uniform double locked seams that with it increased strength among tubes. This strong seam is crucial for air duct fabrication used in commercial and industrial applications.

SBKJ SPIRAL TUBEFORMER is an interesting and automatic manufacturing machine of spiral tubes in double lock seaming. That means the machine is capable of doing almost all the work on its own! It gives a proper shape to the metal sheets and produces cuts on these sheets at desired lengths so that one side-sheet can be inserted within two adjacent locks, which ensures a strong double lock connection between opposite ends of everything. What you get is accurately sized lengthwise and in diameter spiral tubes, a very crucial for ensuring that everything mates properly. Its automatic function means that the occurrence of human errors is minimised, so you can be sure every tube produced is consistent and of a high standard.

With respect to the double lock seaming technique, the SBKJ SPIRAL TUBEFORMER help you form spiral tubes with great speed and efficiency. This automation ensures that the machine has to do all the work while it producing tubes with much accuracy and speed. It enables customers to get their hands on their merchandise just in time, this is critical for companies that require immediate action. This machine can produce hundreds of tubes in one day, while requiring minimal personnel on it. The SBKJ SPIRAL TUBEFORMER is the best option for you to produce mass volumes of double lock seam spiral tubes because it has high speed and efficiency.