Vous vous êtes déjà demandé comment fabriquer un tube en spirale ? C'est assez intéressant ! Grâce aux progrès de la technologie, le processus de production est désormais plus rapide et plus simple qu'auparavant. Donc, dans le cas de la production de tubes en spirale, si nous parlons des types de techniques qui peuvent être utilisées, l'une des meilleures techniques consiste à utiliser la méthode de soudure Double Lock Seaming. Cette technique est très appréciée car elle apporte solidité et sécurité aux fixations métalliques. Dans cette méthode de soudure Double Lock Seaming, deux feuilles de métal sont connectées le long de leurs bords pour ensuite les façonner en un tube en spirale. Ces tubes ont une couture double verrou spéciale. La couture rend plus difficile la séparation des tubes, ce qui les rend solides et fiables pour de nombreux usages.

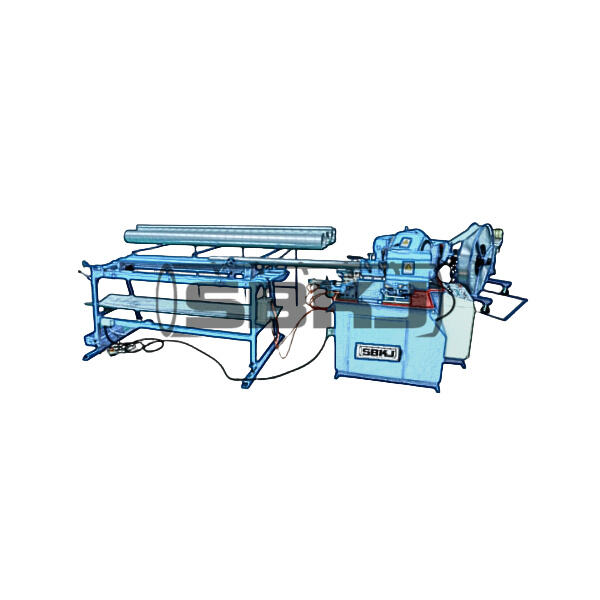

Les machines conventionnelles ont clarifié les choses en ce qui concerne les tubes spirales. Ces tubes doivent être fabriqués avec une grande précision, ce qui rend également nécessaire une bonne machine Tubeformer. Par exemple, la machine SBKJ Spiral Tubeformer est une machine à usage spécial conçue pour produire des tubes spirales en utilisant le procédé de soudure double verrouillage. Une autre particularité remarquable de cette machine est que l'automatisation qu'elle intègre fait des merveilles ; le processus automatisé améliore la précision et la stabilité lors de la fabrication de tubes spirales. Après des années d'expérience, SBKJ a produit l'une des meilleures machines disponibles sur le marché aujourd'hui. Les opérateurs peuvent spécifier des longueurs et dimensions très précises des tubes souhaités avec cette machine, garantissant ainsi un ajustement parfait.

La technique de soudure Double Lock est un moyen ingénieux de joindre deux pièces métalliques de manière extrêmement sécurisée. Elle crée un lien physique durable qui peut résister à diverses forces directionnelles comme le vent, ou à des forces directionnelles opposées telles que la pression. La soudure double lock est l'option préférée pour la fabrication de tubes spirales en raison de cette robustesse. Cependant, avec la SBKJ SPIRAL TUBEFORMER, elle est encore plus sûre et fiable. La machine produit des coutures doublement verrouillées parfaitement uniformes, augmentant ainsi la force entre les tubes. Cette couture solide est cruciale pour la fabrication de conduits d'air utilisés dans les applications commerciales et industrielles.

SBKJ SPIRAL TUBEFORMER est une machine de fabrication intéressante et automatique de tubes spirales en double emboîtement. Cela signifie que la machine est capable de faire presque tout le travail toute seule ! Elle donne une forme appropriée aux tôles métalliques et réalise des coupes sur ces tôles à des longueurs désirées, de sorte qu'une tôle latérale peut être insérée dans deux emboîtements adjacents, ce qui assure une connexion solide en double emboîtement entre les extrémités opposées. Le résultat est des tubes spirales précisément dimensionnés en longueur et en diamètre, ce qui est très crucial pour garantir que tout s'assemble correctement. Sa fonction automatique signifie que l'apparition d'erreurs humaines est minimisée, donc vous pouvez être sûr que chaque tube produit est cohérent et de haute qualité.

En ce qui concerne la technique de soudure en double verrouillage, l'SBKJ SPIRAL TUBEFORMER vous aide à former des tubes spirales avec une grande rapidité et efficacité. Cette automatisation garantit que la machine effectue tout le travail tout en produisant des tubes avec une grande précision et rapidité. Elle permet aux clients de recevoir leur marchandise juste à temps, ce qui est crucial pour les entreprises nécessitant une action immédiate. Cette machine peut produire des centaines de tubes en un jour, avec un personnel minimal requis. L'SBKJ SPIRAL TUBEFORMER est la meilleure option pour produire de grandes quantités de tubes spirales à double verrouillage, grâce à sa vitesse et son efficacité élevées.