Hi, young readers! Have you ever wondered where metal objects come from? This may be a magic task, but it is merely a modification that requires sheets metal machinery. These machines play a very crucial role in the manufacture of several kinds of metal products. Things such as pipes, ducts and even building parts constructed with these machines. In this article, you are going to know more about the feature of sheet metal machines and how it assists people in producing how different kinds of wonderful items made of metals. SBKJ SPIRAL TUBEFORMER is your partner to manufacture high quality sheet metal machines and support you in the projects and goals that you are pursuing.

Sheet Metal Machine Sheet metal machine is a type of machine used for cutting and forming metals into various shapes, sizes, and pieces. Sheet metal machines basically differ with respect to the work they perform. To illustrate; there are presses, roll formers and shears. The machines work together in factories to make end-products, such as pipes, ducts and roof. Familiarity with sheet metal machines is an essential aspect of choosing the most suitable machine for your needs and the product you want to manufacture.

Precise Cuts & Shapes — One of the excellent benefits of sheet metal machine is that it cuts the metals in precise manner and shape. It ensures that the items that are created will have a good quality and they will fit with each other perfectly. With these machines, manufacturers are able to manufacture products that are durable and safe.

Presses The presses are machines in which pressure that is used to shape metal sheets нinto various forms. There are various types of presses, such as punch presses that perforate metal, and hydraulic presses, which apply fluid pressure for shaping purposes. Each kind of press has unique applications to assist in manufacturing products.

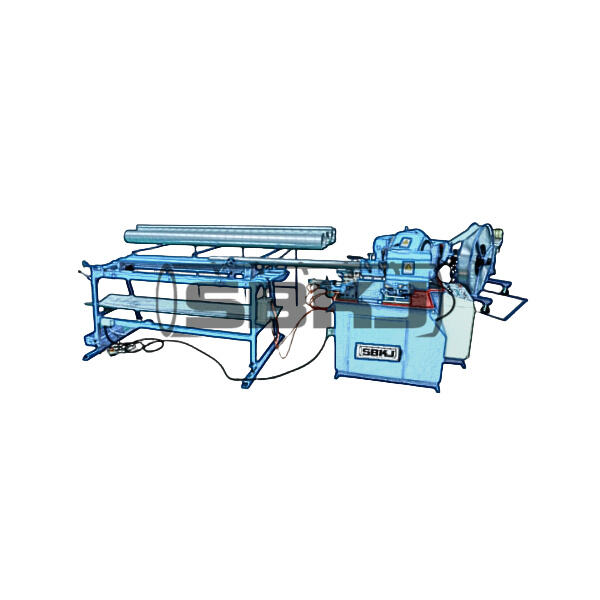

Roll Formers — These machinery use rollers to shape metal sheets into various configuration. They are able to make long, continuous, and very useful shapes and become used in construction. There are several different types of roll formers, including tube roll formers which create pipes and sheet roll formers which develop sheets for many uses.

Shears: machines with sharp blades that are utilized to cut metal sheets into a desired size and shape. This makes them very useful in the manufacturing process as they can chip through metal quickly and accurately. The types of shears include foot shear, operated with the help of foot pedals, and hydraulic shears powered by hydraulics that make cutting easier.

CNC (Computer Numerical Control)– CNC is a technology that involves the use of computers to control sheet metal machine tools, This enables instructions to a computer for issuing commands, which makes the machines more precise and quicker followed byanglais.r. CNC allows manufacturers to produce intricate parts in an efficient manner.