Vous êtes-vous déjà demandé comment le conduit de votre maison ou de votre bureau est fabriqué ? Seriez-vous surpris d'apprendre qu'il est fabriqué à l'aide d'un type spécifique de machine appelé Lock Former ! Le Lock Former est une machine très cool et puissante pour former de la tôle qui sera utilisée pour fabriquer des conduits. C'est un processus très rapide et précis, qui est obligatoire pour la production de produits de qualité.

Lock Former est la meilleure machine pour fabriquer des produits en tôle. Elle permet de donner forme à une variété d'objets, par exemple, des gaines rectangulaires, des gaines spiralées et des gaines rondes. Elle est simple à utiliser, ce qui signifie que les nouveaux utilisateurs comprendront rapidement. Le Lock Former est également incroyable car il produit toujours les bonnes formes. Cela améliore vraiment la précision du fonctionnement des gaines, peu importe où elles sont installées.

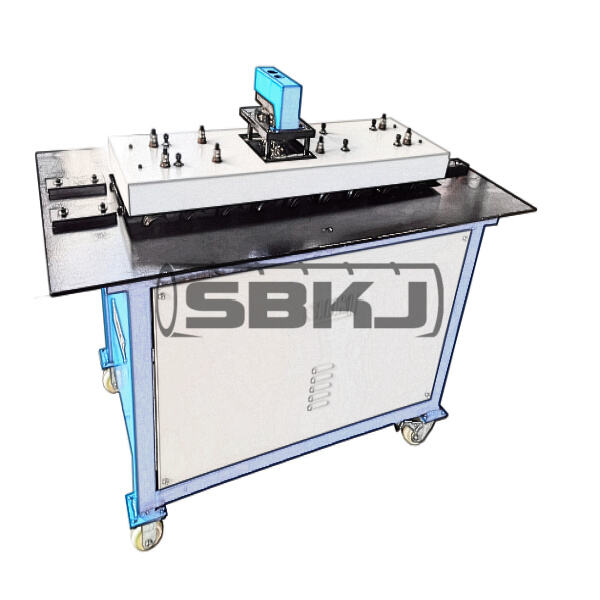

Équipé d'un moteur moderne puissant, l'électronique du Lock Former produit également rapidement des conduits. La machine est ensuite alimentée pour produire efficacement en masse des pièces de conduit viables grâce à un moteur à couple élevé. Les rouleaux de la machine sont spécialement conçus pour bien saisir la tôle métallique. Cette prise est en effet cruciale pour former le métal exactement dans les bonnes configurations, afin que chaque pièce de conduit soit fabriquée correctement. Ainsi, le Lock Former est assez essentiel pour toute organisation travaillant avec des matériaux métalliques.

J'adore particulièrement l'option de conduit spiralé ! Cette fonction génère une forme spiralée par laquelle les conduits permettent un passage d'air fluide. Elle favorise un débit d'air doux — ce qui est utile pour le confort dans les espaces et minimise le bruit des équipements de chauffage et de refroidissement. Le conduit spiralé peut également économiser de l'espace dans un bâtiment car il prend moins de place lors de l'installation, ajoutant ainsi de la valeur aux projets de construction.

Former des tôles peut être très chronophage et assez complexe. Mais, c'est ici que le Lock Former se distingue ! Il vous aide à accélérer l'ensemble du processus. La tôle est enfoncée dans les rouleaux de la machine, permettant d'obtenir des formes précises à chaque utilisation. Les Lock Formers sont équipés d'un moteur puissant qui permet une fabrication rapide de toutes sortes de formes de tôles, et c'est l'un de ses principaux avantages.

Pour ceux d'entre vous qui gèrent une entreprise de fabrication de tôles, le Lock Former peut augmenter vos profits. Cette machine fabrique des gaines en un rien de temps avec une précision au millimètre, ce qui vous permet d'améliorer la qualité globale de vos produits. Vous obtiendrez également des produits plus fins, et des clients satisfaits ne peuvent être que bénéfiques pour votre activité. De plus, le Lock Former peut également accélérer votre travail, vous permettant ainsi de traiter plus de projets que jamais auparavant.

En conclusion, le Lock Former est une machine excellente et a révolutionné notre industrie de la tôle. Elle permet une formation sans couture et précise de formes parfaites en un minimum de temps, améliorant la vitesse et la qualité pour les tôles. Cette caractéristique du conduit spiralé aide à améliorer les fonctions de chauffage, de refroidissement et de ventilation des systèmes HVAC de manière plus efficace, offrant un environnement de vie et de travail confortable exactement là où nous en avons besoin, même avant que l'air froid ou chaud ne commence.