Le soudage est un processus unique pour relier deux surfaces métalliques. Cela est assez essentiel pour divers travaux que nous faisons tous les jours, tels que l'assemblage de voitures, la construction de bâtiments et la fourniture d'autres outils. Le soudage existe en une douzaine de types, le saviez-vous ? L'un d'eux s'appelle le soudage par point, qui est couramment utilisé pour créer des joints continus et solides entre les métaux. Cependant, c'est un type de soudage extrêmement précieux car ce type de soudure produit des produits très robustes et durables.

Les machines à soudure par points sont des machines spéciales qui permettent d'effectuer ce type de soudure de manière beaucoup plus rapide et facile. Elles vont électriquement lier deux pièces métalliques ensemble, ce qui crée un lien très solide. Cette étape est cruciale dans le processus car, sans elle, la capacité à produire rapidement des produits de qualité pourrait faiblir.

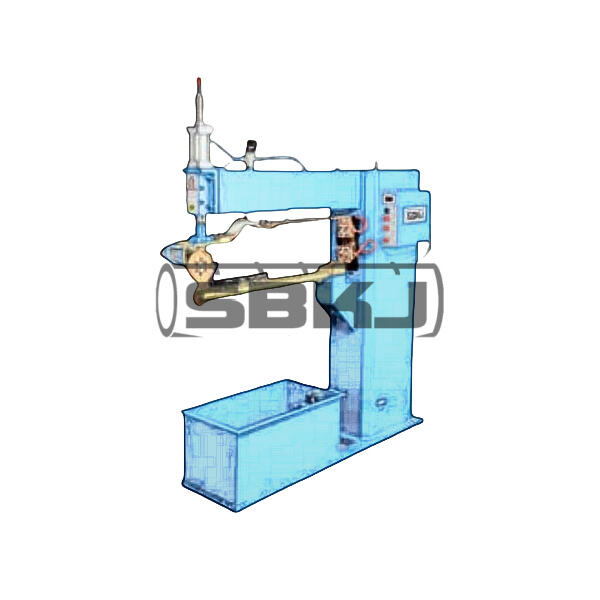

SBKJ SPIRAL TUBEFORMER a développé une nouvelle génération de machines à soudure par couture qui est largement utilisée dans divers secteurs industriels. Ces machines sont conçues pour une soudure par couture rapide et sans complications. Elles sont faciles à utiliser, donc même quelqu'un qui n'a jamais soudé auparavant peut apprendre à les utiliser assez rapidement. Cela compte parce que cela permet à plus de personnes d'utiliser ces machines, elles produisent des produits.

Avant les machines à soudure par couture, il était nécessaire de réaliser des soudures individuellement. C'était un processus long et nécessitant beaucoup de compétences. Les soudeurs devaient être particulièrement prudents et pratiquer plusieurs fois pour acquérir de la maîtrise. Cependant, avec les machines à soudure par couture disponibles aujourd'hui sur le marché, effectuer des soudures n'a jamais été aussi simple ou rapide pour toutes les parties concernées.

Actuellement, les machines de soudage par couture SBKJ SPIRAL TUBEFORMER sont utilisées dans divers secteurs par de nombreuses entreprises. Implicitement, elles sont utilisées pour des pièces de camions jusqu'à des composants d'avion. Ces machines sont extrêmement efficaces, réduisant les déchets et facilitant le temps nécessaire pour fabriquer ces produits. Cela permet aux entreprises d'augmenter le nombre d'articles qu'elles produisent en un temps beaucoup plus court, bénéficiant ainsi à la fois aux entreprises et aux clients.

L'une des caractéristiques des machines de soudage par couture SBKJ SPIRAL TUBEFORMER est leur rapidité et leur précision. Elles peuvent souder des coutures en quelques secondes, bien plus vite qu'en le faisant manuellement. Grâce à cela, les machines travaillent à la même vitesse à chaque fois, sans erreurs. Cela est extrêmement crucial car cela garantit que les soudures sont toujours de haute qualité, peu importe le nombre de produits fabriqués.

L'utilisation des machines est aussi simple que d'insérer deux pièces métalliques que vous souhaitez joindre dans chaque machine. La machine va ensuite faire passer un courant électrique le long de la couture pour effectuer le soudage. Vous retirez la pièce terminée et vous êtes prêt à souder la prochaine partie dès que le soudage est terminé. Le soudage se fait rapidement et sans effort, ce qui aide à maintenir le flux de production.