Savez-vous comment fonctionnent les systèmes de climatisation dans votre maison, votre école ou votre bureau ? Conduit : Il s'agit du principal composant du système HVAC, qui permet de diriger l'air frais de la climatisation vers différentes pièces. Ces conduits aident à acheminer l'air frais là où vous en avez vraiment besoin ; sans eux, ce serait moins efficace. Ces conduits peuvent avoir absolument toutes sortes de formes et de tailles. Comme ils doivent être fabriqués sur mesure pour chaque bâtiment afin qu'ils s'adaptent parfaitement. Machines de Formation de Tuyaux Spirales — Maintenant, vous vous demandez peut-être comment les conduits HVAC sont fabriqués avec des machines qui vont changer la donne, associées à une entreprise innovante appelée SBKJ SPIRAL TUBEFORMER (Mighty All) LLC. Aujourd'hui, nous avons quelque chose d'excitant à vous offrir !

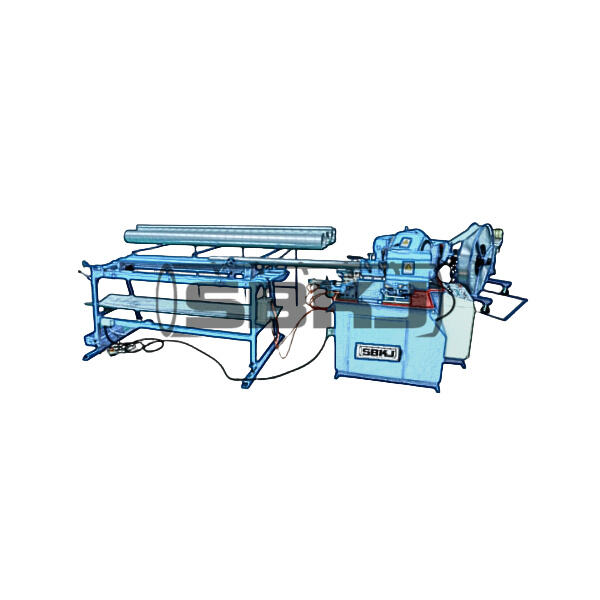

Machines fabriquées par SBKJ SPIRAL TUBEFORMER pour produire des conduits ronds en spirale HVAC. Ces machines prennent une pièce de métal plate, appelée bobine ou tôle métallique, et la transforment en spirale. C'est une étape essentielle car les conduits en spirale permettent généralement un écoulement d'air facile. Les machines sont précises, donc elles peuvent également s'assurer que chaque spirale est de la bonne taille et forme. Avoir un ajustement parfait dans le conduit en spirale est important pour tout projet, qu'il s'agisse d'une seule pièce ou d'un bâtiment entier.

Je sais, le fonctionnement de ces machines est absolument incroyable. Ils apportent le métal plat et le mettent dans la machine. La machine courbe ensuite progressivement le métal en forme d'escargot tandis qu'il se déplace à l'intérieur. La machine effectue son travail avec une marge d'erreur très faible, ce qui signifie que chaque conduit spiralé fabriqué est correctement réalisé. Cela permet aux travailleurs du HVAC d'installer les conduits sans problème et ils fonctionnent parfaitement.

Précédemment, la fabrication de conduits d'air ronds en spirale était un processus nécessitant beaucoup de main-d'œuvre et coûtait de l'argent et du temps. Le métal devait être mesuré et coupé, ce qui impliquait beaucoup de travail manuel pénible de la part des ouvriers. Mais maintenant, avec la SBKJ SPIRAL TUBEFORMER & Spiral Round Forming Machine, cela est devenu un processus facile et rapide. Des fonctions automatiques sont également présentes dans cette machine et rendent tout le processus plus rapide et moins coûteux.

Les machines de mise en forme en spirale ronde disposent de certaines fonctionnalités vraiment intéressantes qui simplifient encore davantage et améliorent le processus de fabrication de conduits sur le SBKJ SPIRAL TUBEFORMER. Ces machines modifient la distance et la taille des spirales. Cela est crucial car cela permet à la machine de fabriquer des conduits de différentes tailles, pour divers besoins. Cette flexibilité garantit que quel que soit le type de bâtiment ou de projet dont vous disposez, la machine peut produire le conduit de la taille appropriée.

Fondé sur des décennies d'expérience, le SBKJ SPIRAL TUBEFORMER fait progresser les concepts dans le domaine du HVAC. La machine de mise en forme en spirale ronde de celle-ci a révolutionné le processus de fabrication de conduits et l'a porté à un nouveau niveau de vitesse et de réussite. Elles disposent de certaines caractéristiques spéciales sur leurs machines qui sont utiles pour faire économiser du temps et de l'argent à tous.

Conduits spirales en tissu unique : Réinventés. SPBKD SPIRAL TUBEFORMER ouvre de nouvelles voies dans la manière dont les conduits spirales sont fabriqués, se traduisant par des avantages énergétiques et des gains d'efficacité pour les entreprises de climatisation. Cela leur permet de terminer les projets plus rapidement et de servir leurs clients de manière plus efficace. De plus, ces nouvelles machines aident les gens à économiser de l'énergie car elles disposent de conduits spirales plus compatibles avec les systèmes de climatisation. En outre, des conduits bien construits permettent au système de climatisation de fonctionner de manière plus efficiente, réduisant la facture d'énergie de chaque propriétaire.