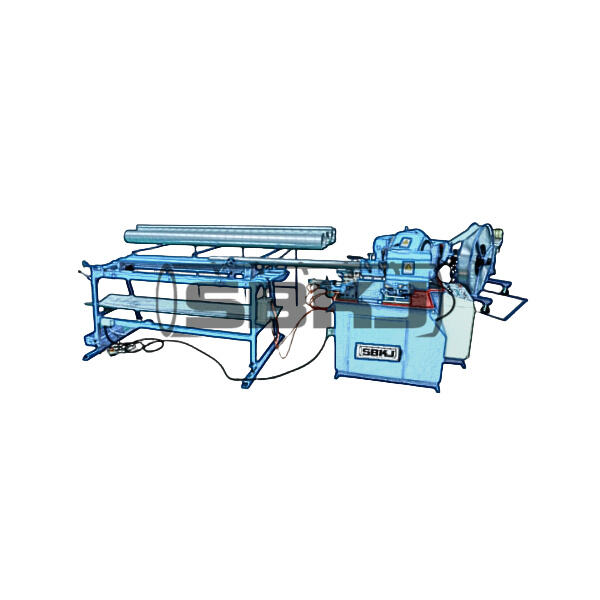

Par exemple, saviez-vous que la climatisation dans votre maison ou à l'école vous rafraîchit par une journée chaude ? C'est vraiment fascinant ! Cet air frais est acheminé dans toute votre maison grâce à des gaines. Celles-ci sont importantes car elles distribuent l'air frais ou chaud dans tout le bâtiment afin que tout le monde soit confortable. Vous avez probablement été curieux à leur sujet mais n'avez jamais demandé comment elles sont fabriquées ? Découvrez la SPIRAL TUBEFORMER SBKJ, une entreprise. Cette machine unique a optimisé son processus de fabrication, rationalisant les opérations de production nécessaires en une solution automatisée brevetée qui réalise cette production bien plus rapidement que les modèles précédents.

La fabrication de gaines était autrefois une tâche très inefficace et fastidieuse. Elle nécessite beaucoup de travail et de temps, car les ouvriers doivent usiner manuellement des tôles métalliques. La réalité est que, fabriquer des gaines est maintenant devenu plus facile grâce à la machine incroyable SBKJ SPIRAL TUBEFORMER. C'est une machine fabricante de solutions de virages/gaines qui peut produire des gaines spiralées en un court laps de temps et avec précision. Les spirales sont importantes parce que ces spirales sont significatives, car elles ne laissent pas de miettes d'articulations non connectées par où l'air pourrait s'échapper. Cela aide à garder l'air froid là où il doit être, fonctionnant bien mieux avec moins d'efforts.

Machine polyvalente : Le SBKJ SPIRAL TUBEFORMER est une machine polyvalente qui permet de fabriquer des conduits spirales de différentes tailles. Et c'est génial parce que vous pouvez l'utiliser pour tout type de bâtiment, qu'il s'agisse d'une maison individuelle ou de magasins et locaux commerciaux plus grands. La machine est tellement efficace et effectue la tâche rapidement. Elle dispose de fonctionnalités spéciales qui la rendent plus opérationnelle et n'exige pratiquement aucune assistance. Un ordinateur la contrôle pour s'assurer que tout se fait rapidement et avec précision. Grâce au système de chargement automatique qui permet de continuer à alimenter en continu des tôles métalliques, la machine peut produire des conduits sans interruption.

Avec la climatisation, chaque pouce carré d'air compte ! C'est pourquoi la machine SBKJ SPIRAL TUBEFORMER est capable de s'assurer que chaque conduit est fabriqué à la perfection. Ces fonctionnalités automatiques aident à plier et façonner chaque conduit parfaitement en place - une exigence importante pour un bon débit d'air. Cela signifie que l'air peut circuler sans heurt, réduisant ainsi les pertes d'énergie. Lorsqu'un système de climatisation fonctionne correctement, il économise des coûts énergétiques, ce qui est bénéfique pour tous !

Puisque aucun immeuble n'est identique, le SBKJ SPIRAL TUBEFORMER offre une approche plus personnalisable de leur machine. Cela signifie que vous pouvez modifier la machine pour qu'elle corresponde à vos besoins, afin qu'elle convienne à votre bâtiment ou projet. Vous pouvez l'adapter pour concevoir des gaines dans des dimensions et des formes appropriées pour votre bâtiment. De plus, la machine travaille avec divers types de matériaux métalliques, tels que l'aluminium ou l'acier inoxydable, en fonction des exigences du projet. Cela donne aux constructeurs et fabricants beaucoup de flexibilité.

Dans le domaine de la fabrication, SBKJ SPIRAL TUBEFORMER reconnaît que le temps c'est de l'argent. C'est pourquoi leur machine à fabriquer des conduits spirales répond au besoin de connexion avec d'autres machines dans une ligne de production. Son système d'alimentation lui permet de continuer à produire des conduits sans s'arrêter. Ces fonctionnalités automatiques garantissent que chaque conduit est fabriqué de manière précise et correcte - un aspect crucial dans un processus aussi sensible au contrôle qualité. Grâce à cela, les fabricants peuvent bénéficier d'une productivité améliorée, de résultats rapides et d'une fabrication de conduits coûteuse efficace.