Qu'est-ce que la soudure, et pourquoi est-elle importante ? Lorsque vous pensez à la soudure, vous pensez au processus de combinaison de matériaux pour créer quelque chose de plus solide. Il existe plusieurs méthodes différentes de soudure, mais l'une des méthodes les plus précieuses est celle que vous pouvez utiliser Machine de découpe laser . Ce type unique de soudeur utilise des lasers pour joindre des matériaux, et il offre plusieurs avantages par rapport à la soudure conventionnelle, que l'homme a utilisée pendant des siècles.

Par exemple, un grand avantage d'un soudeur à joint laser est qu'il fonctionne de manière significativement plus rapide par rapport aux autres techniques de soudage. Dans le soudage ordinaire, une grande quantité d'énergie est consommée pour chauffer les matériaux à assembler, ce qui en fait un processus long. Cela prend beaucoup de temps et demande beaucoup de travail. Mais avec un soudeur à joint laser, c'est plus rapide et plus précis. Le laser chauffe les matériaux extrêmement rapidement et les relie de manière propre, minimisant ainsi le temps de processus. Ce processus ultra-rapide aide les fabricants à produire des produits plus rapidement, ce qui est bon pour les affaires. Empreinte environnementale réduite : Moins de matériel est consommé pendant le soudage, réduisant ainsi les déchets.

Un autre avantage de tête de formage 1602 c'est qu'il crée des soudures avec des joints solides et sans coutures visibles. Les techniques de soudage traditionnelles ont tendance à créer des lignes ou des joints qui peuvent constituer un point plus faible dans le matériau. Ces coutures rendent également le produit final moins attractif visuellement. Mais avec un soudeur laser, l'assemblage est tellement serré qu'il est difficile de discerner où les matériaux se sont connectés. Ces processus renforcent encore les matériaux et favorisent la durabilité. Cela crée un produit qui est non seulement plus solide, mais aussi plus esthétique, ce qui est important pour beaucoup de gens et d'entreprises.

Pour ces raisons, le soudage de matériaux minces peut être difficile; il faut une chaleur et une pression précises pour les lier suffisamment. Toutefois, si la chaleur est trop intense, les matériaux minces peuvent se déformer ou se détériorer. Le soudeur à couture laser est idéal pour les matériaux minces. Le laser génère une chaleur très concentrée et peut souder facilement et proprement même les matériaux les plus fins. Ce travail avec des matériaux minces apporte aux fabricants des produits durables et solides sans se soucier de ruiner les pièces jointes.

La capacité de contrôler le processus de soudage avec un soudeur à couture laser est un autre avantage majeur. Vous pouvez varier le laser pour donner exactement la bonne quantité de chaleur et de pression pour faire une soudure parfaite. Cela signifie que le produit final est très propre, sans coutures ni joints. Une finition lisse rend le produit plus beau et plus durable. Un produit mieux fabriqué peut résister à plus de stress et durer plus longtemps, ce qui est bon pour le fabricant et le client.

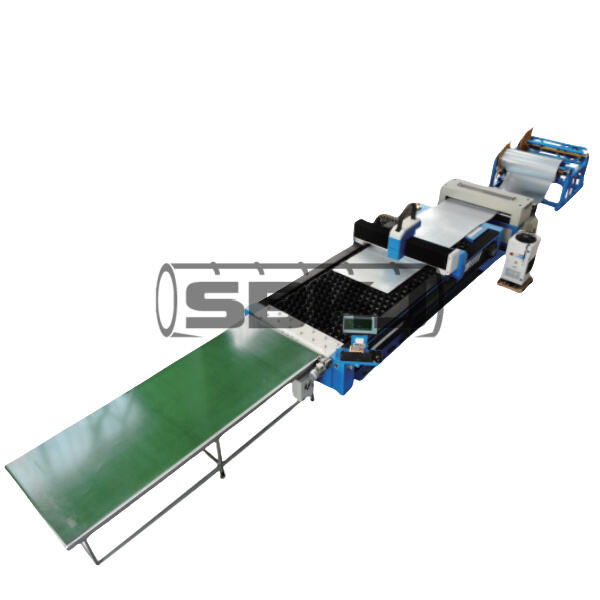

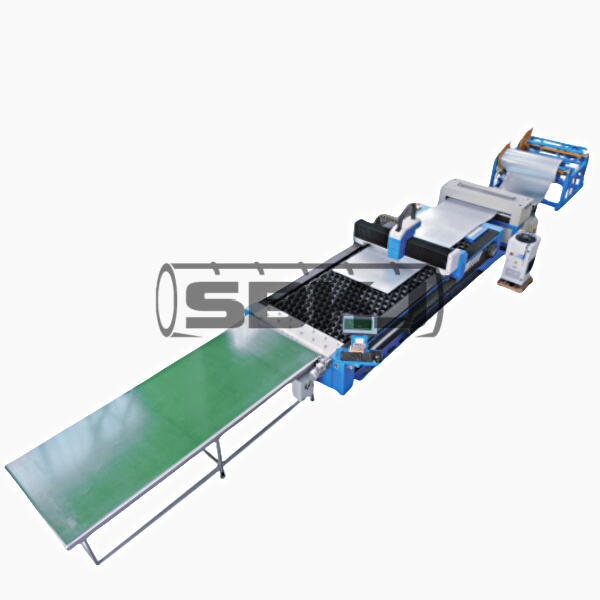

SBKJ SPIRAL TUBEFORMER propose divers types de soudeurs à joint par laser pouvant être utilisés pour de nombreux travaux de soudage. Des soudeurs économes en énergie et conviviaux offrant une qualité élevée. Cela signifie que vous pouvez produire des produits de haute qualité sans complications. Avec nos soudeurs à joint par laser, vous obtenez une soudure robuste, un assemblage rapide et un excellent contrôle. Que ce soit du matériau en feuille mince ou plus épais, cela peut rendre votre travail plus facile en permettant d'effectuer un travail exceptionnel avec nos soudeurs.

Le groupe SBKJ est basé dans le delta du Yangtsé, près de Shanghai, en Chine. SBKJ a plus de 30 ans d'expérience dans la production de spirales tubulaires depuis 1995. SBKJ a obtenu les certificats de soudure à joint laser et CE. La spirale tubulaire SBKJ peut répondre aux normes DIN, BS, Euroorm et Smacna. Nos clients proviennent de plus de 60 pays dans le monde.

le soudoir à laser par couture propose des services de fabrication sous licence. Vous pouvez choisir d'éliminer le logo SBKJ de votre appareil ou demander une couleur personnalisée pour l'appareil. La langue utilisée par le logiciel peut être définie si vous fournissez des traductions pour des langues qui ne sont pas majeures. Nous pouvons également personnaliser l'équipement dont vous avez besoin en fonction de vos exigences de production.

SBKJ est un soudoir à laser par couture et est le fabricant le plus renommé et leader de conduits spirales avec plusieurs inventions brevetées, comme le siliteur volant et le crinnper volant. Les efforts de recherche et développement de SBKJ sont à la base de nos tubeformeurs automatiques, qui produisent des conduits de haute qualité à moindre coût.

Nous disposons d'un service client dédié et d'un soudeur à laser pour les coutures spécifiquement attribué à chaque client, en plus d'une ligne directe After-Sales Service fixe et d'un groupe WeChat dédié au service après-vente. Nous sommes facilement joignables sur Internet. En nous appuyant également sur l'Internet, nous pouvons vous assister rapidement et vous aider à résoudre des problèmes. Les équipements SBKJ bénéficient d'une garantie de 1 an et d'une maintenance payante à vie.