Le soudage au laser est un processus impliquant une fusion entre les deux parties, qui utilise un laser pour lier des couches très minces de matériaux solides ensemble. Un laser est un faisceau de lumière extrêmement intense qui peut être dirigé et focalisé sur un point du métal. Le faisceau laser, en touchant le métal, le chauffe à une très haute température, ce qui fait fondre sa surface. Pensez à la façon dont la crème glacée fond lorsqu'on la sort dehors par une journée chaude ! Une fois refroidi, le métal fondu se solidifie, reliant les deux morceaux de métal solidement l'un à l'autre. Ce procédé aide à créer des joints durables et permanents pour les métaux.

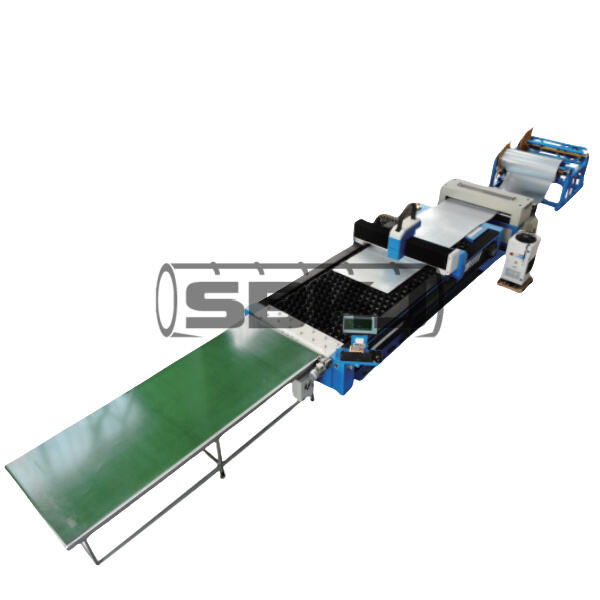

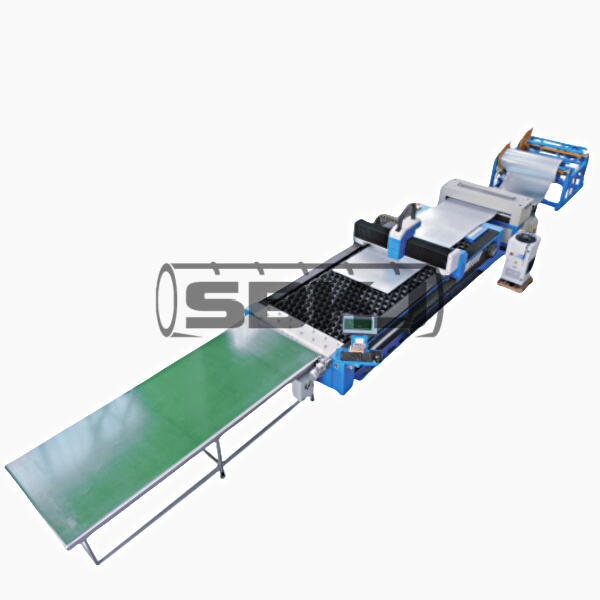

Le soudage au laser révolutionne le travail des usines DANS UNE GRANDE MESURE ! Autrefois, ils le faisaient avec un chalumeau et une flamme. Cette méthode pouvait être risquée et était plutôt imprécise, ce qui signifiait qu'obtenir le soudage parfait n'était pas facile. Maintenant, les usines utilisant tête de formage 1602 peut être bien plus précis — et peut donc créer des assemblages beaucoup plus solides entre des morceaux de métal. Cela conduit à de meilleurs produits et permet également aux usines de produire plus rapidement et efficacement. Ainsi, de nombreuses usines adoptent le soudage au laser dans leur processus de fabrication.

Le soudage au laser : une excellente option pour les petits projets ! Il est extrêmement fin, ce qui lui permet d'assembler même les plus petits composants sans erreur. Cela est utile pour fabriquer des machines miniatures ou des pièces de jouets. De plus, le soudage au laser est rapide et ne gaspille pas de matériaux, ce qui signifie que même les petits projets peuvent être terminés en un court laps de temps et avec un minimum de déchets. C'est une méthode intelligente pour travailler sur de petits projets et cela aide certainement les gens à économiser du temps et de l'argent.

Il est nécessaire de connaître le soudage laser (si vous voulez en apprendre davantage, si vous voulez savoir). Maîtriser bien le soudage laser demande beaucoup d'entraînement et de compétences, premièrement. Seuls les professionnels formés qui savent ce qu'ils font peuvent utiliser un soudeur laser. Un autre point est que les machines de soudage laser ont tendance à être très coûteuses, et donc, toutes les entreprises ne peuvent pas se les offrir. Enfin, bien que le soudage laser soit la meilleure solution pour de nombreux projets, il n'est pas nécessairement la bonne solution pour chaque application. Cette méthode peut ne pas être la meilleure option pour vos besoins, alors prenez en considération ce dont vous avez besoin avant de suivre cette voie.

Le soudage au laser, pour les grands projets, est un véritable allié. Il est extrêmement rapide, permettant de produire un grand volume de produits en peu de temps et permettant ainsi aux entreprises de répondre à la demande. De plus, étant précis, le soudage au laser produit des objets de grande taille avec peu de déchets. Ce qui est vraiment bien car cela économise des matériaux et de l'argent. De plus, le soudage au laser crée des produits solides et durables. Cela signifie qu'en achetant un article fabriqué par soudage au laser, il restera en bon état longtemps après son achat.