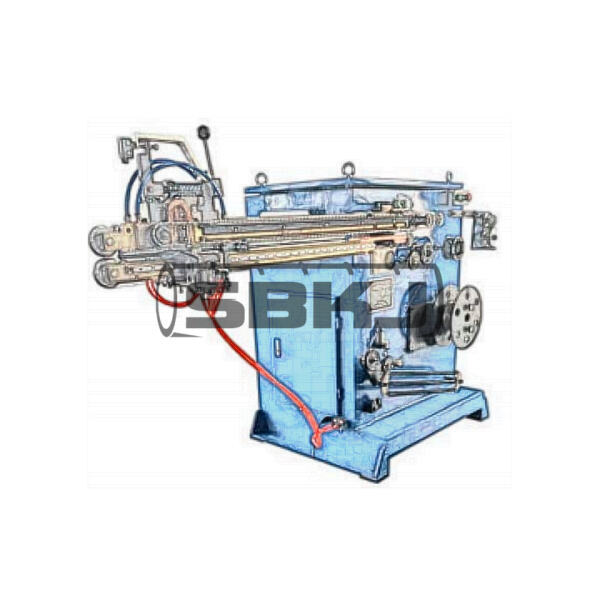

Vous vous êtes déjà demandé comment les choses sont fabriquées ? Il est fascinant de voir comment toutes les petites pièces s'assemblent pour créer quelque chose de nouveau. Question n°1 : Vous vous êtes déjà demandé comment deux morceaux de métal peuvent être si solidement collés ensemble ? Eh bien, pour répondre à cette question — c'est un appareil unique que nous appelons tête de formage 1602 ils combinent également des composants métalliques à l'aide de l'électricité, ce qui les rend très utiles. Lorsque le courant passe à travers le métal, il génère de la chaleur, ce qui fait que les pièces se lient. Les machines de soudage par résistance sont des appareils puissants qui permettent la production de nombreuses choses que nous rencontrons dans notre vie quotidienne, telles que les automobiles et les appareils électroménagers. Ces machines ont évolué au fil des ans, les rendant plus efficaces et utiles pour les usines.

La machine à soudure par résistance présente quelques avantages significatifs qui la rendent excellente pour une utilisation en usine. L'un des plus grands avantages est qu'elle forme une bonne liaison entre des pièces métalliques qui ne se combinerait pas autrement. Cette connexion profonde est importante pour créer des produits durables qui sont résilients et long-lasting. En dehors de cela, les machines à soudure par résistance produisent un minimum de déchets. Elles fonctionnent en générant de la chaleur uniquement au point précis où les pièces de métal entrent en contact, de sorte que le reste du métal reste froid et inchangé. Cela signifie non seulement moins de matériaux restants à trier, mais cela contribue également à réduire les fumées nocives que d'autres techniques de soudage peuvent générer.

Les machines de soudage par résistance sont également incroyables car elles se révèlent utiles pour souder des métaux de différentes épaisseurs. Cela signifie qu'il n'a pas d'importance que les pièces métalliques soient épaisses ou fines, les machines peuvent créer le bon type de lien entre elles. Elles peuvent aider à rendre la connexion juste ce qu'il faut, ni trop ni trop peu. Cette capacité à s'adapter est extrêmement utile pour fabriquer différents types de produits. Enfin, ces machines économisent également beaucoup de temps et augmentent la productivité des travailleurs. Elles sont plus rapides que de nombreuses autres méthodes de jonction de pièces métalliques, ce qui en fait l'idéal pour une production de masse lorsque le même objet doit être produit rapidement et en grande quantité.

L'une de ces innovations est un nouveau système de refroidissement à eau. Ce design unique empêche les machines de surchauffer, ce qui pourrait prolonger leur durée de vie. Des machines fonctionnant à une température plus basse peuvent produire plus de produits en moins de temps. Modernes Machine à conduits d'air les machines ont un autre avantage : elles sont capables de fonctionner automatiquement. Il est indiqué que les machines peuvent effectuer certaines tâches de manière autonome, ce qui conduit à une plus grande précision et cohérence. Cette automatisation permet même la réalisation d'un grand nombre de lignes de programme de manière rapide et efficace, ce qui est très bénéfique pour les organisations qui doivent répondre à une forte demande.

Les machines de soudage par résistance peuvent être utilisées dans une large gamme d'industries et d'applications. L'automobile, l'aérospatial et la fabrication électrique ne sont que quelques-unes des industries les plus courantes qui utilisent ces machines. Par exemple, les machines de soudage par résistance sont cruciales dans l'industrie automobile pour fabriquer des cadres de voiture ou certains composants de moteur. Elles aident à s'assurer que ces pièces sont définitivement assemblées, ce qui est très important pour la sécurité et la fiabilité de tout véhicule sur la route.

Dans le secteur aérospatial, ces machines sont généralement utilisées pour assembler des panneaux métalliques qui forment les cadres des avions. Étant donné le domaine, un assemblage solide et fiable est essentiel car il aide à protéger contre les pannes lors des vols. Les machines de soudage par résistance sont également indispensables dans l'industrie électrique, où elles fabriquent des connecteurs critiques pour la réalisation de câblages et de fils, qui sont les artères d'une machine électrique. Ces machines permettent aux fabricants de produire rapidement et de manière rentable des connecteurs de haute qualité.

Donnez toutes les informations sur l'article de soudage par résistance. Les avantages environnementaux en font également une excellente alternative à de nombreux autres types de méthodes de jonction des métaux, car elles produiront bien moins de déchets que toute autre méthode de jonction des métaux. Elle aide au développement rapide de produits de haute qualité à un coût plus faible pour les organisations grâce à son efficacité et sa rapidité. Cette amélioration globale dans les procédures des entreprises de fabrication est l'un des éléments favorables qui aident les entreprises à se battre et à gagner.