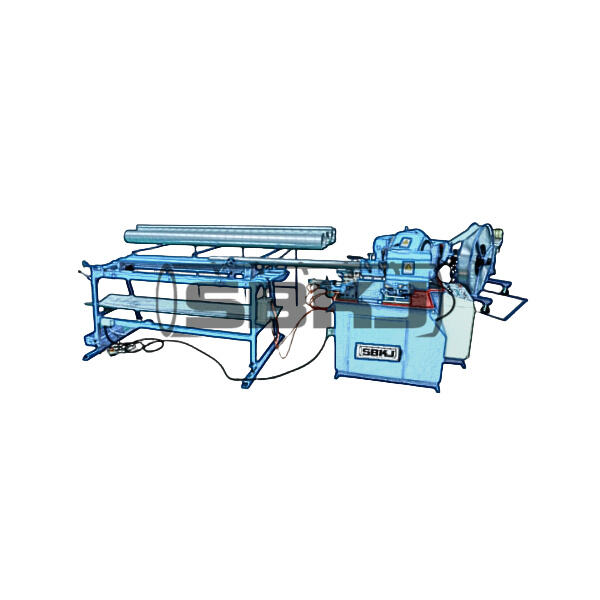

Si vous avez utilisé un conduit rond pour votre climatisation ou votre chauffage, vous vous êtes peut-être demandé à un moment donné comment ces conduits étaient fabriqués. Ils sont essentiels pour la circulation de l'air dans votre maison ou bâtiment. Il existe donc une machine dédiée pour fabriquer ces conduits circulaires ! L'appareil s'appelle le SBKJ SPIRAL TUBEFORMER. Parler de ce type de machine est vraiment utile pour créer des conduits ronds et cet équipement fonctionne rapidement en quelques fractions de secondes. Cela signifie que les conduits sont fabriqués avec perfection — ainsi ils fonctionnent correctement.

Le SBKJ SPIRAL TUBEFORMER fabrique des conduits ronds en un matériau durable pour une longue durée de vie. Ils sont choisis car ils peuvent résister à la pression d'air et aux températures rencontrées dans les systèmes HVC. Les conduits peuvent être créés en toutes formes et tailles selon les besoins de votre projet. Il a un design très convivial avec des boutons et des commandes simples qui vous permettent de créer des conduits rapidement et sans complications. Ceux qui fabriquent ces conduits tous les jours trouvent cela un outil puissant en effet.

L'industrie a connu une évolution dans la construction de gaines avec l'introduction incroyablement innovante de l'SBKJ SPIRAL TUBEFORMER dans les chaînes de production. Il fabrique des gaines rondes bien plus vite qu'à la main, et cette machine devrait être votre premier choix. Fabriquer des gaines manuellement est très chronophage et exige beaucoup de main-d'œuvre. Cependant, avec cette machine, c'est nettement plus rapide et facile. Cela vous permet de produire bien plus en moins de temps, ce qui vous fait économiser de l'argent et permet d'accomplir davantage de travail. Idéal pour les entreprises qui doivent fabriquer des gaines en grande quantité, n'est-ce pas ?

Une autre chose rend également plus facile l'entretien du SBKJ SPIRAL TUBEFORMER. Il est livré avec un manuel qui sert de guide pour entretenir la machine. En suivant les instructions données dans le manuel, vous pouvez vous assurer que votre machine reste en bon état de fonctionnement. Cela signifie que vous économisez davantage à long terme, car si la machine est bien entretenue, elle peut durer des années et des années. Assurément, un entretien régulier est nécessaire pour éviter les problèmes.

Le SbkJ Spiral Tubeformer, développé en combinant une technologie moderne, produit des conduits parfaitement ronds. Sous-système d'une machine dotée d'un système informatique qui contrôle le processus de production des conduits. Ce mécanisme permet d'assurer une précision incroyable pour les conduits – et ainsi, ils s'emboîtent parfaitement. Plus l'emboîtement de vos conduits est précis, meilleure sera l'efficacité du flux d'air de vos systèmes de chauffage et de refroidissement. Cela permet un fonctionnement plus fluide, et peut également économiser de l'énergie – ce qui est bénéfique pour votre porte-monnaie et la planète.

Une flexibilité considérable est offerte par les machines, car elles supportent plusieurs matériaux tels que l'acier inoxydable, l'aluminium et l'acier galvanisé. Chaque matériau possède un ensemble unique de propriétés, et ainsi, vous pouvez utiliser la machine pour une variété de projets en fonction de vos besoins. Par exemple, l'acier inoxydable est fantastique grâce à sa rigidité et à sa résistance à la rouille. Cette polyvalence permet au SBKJ SPIRAL TUBEFORMER d'être utilisé pour différentes applications, car les opérateurs peuvent choisir le matériau optimal en fonction de leurs besoins respectifs.

La machine est rapide, ce qui peut vous faire économiser beaucoup de temps et d'argent. Présentation du SBKJ SPIRAL TUBEFORMER — fabriquez plus de canalisations en moins de temps. Cela signifie que vous pouvez effectuer davantage de travail et gagner plus d'argent. Un taux de production élevé est bénéfique pour tous les parties prenantes concernées, car il aide les entreprises à élargir leur processus de production. De cette manière, cette machine contribuera dans son ensemble à éliminer les tracas liés à la production de canalisations en augmentant la vitesse et l'efficacité.