Avez-vous déjà pensé à la manière de fabriquer des tuyaux et des gaines en métal ? Vous avez probablement observé d'énormes machines qui plient des feuilles de métal et les transforment en tuyaux. Cette machine s'appelle une tête de formage 1602 , et c'est super cool ! Il joue un rôle dans la transformation de feuilles de métal plat en tubes ronds, qui peuvent être trouvés dans de nombreux endroits, des structures aux usines et même à l'intérieur des voitures.

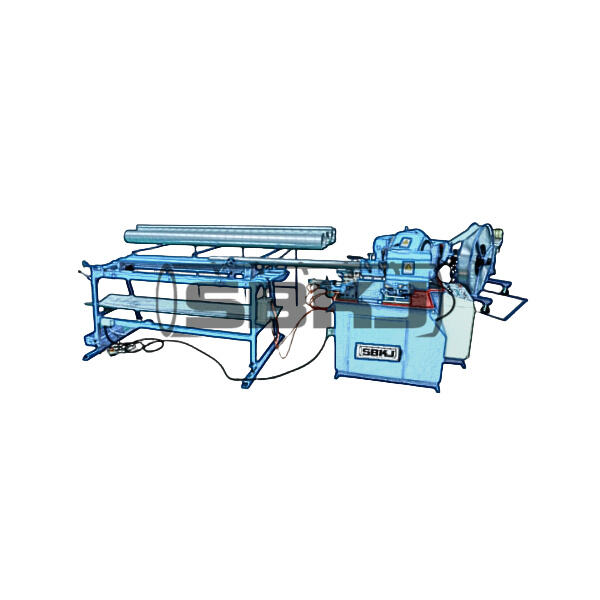

Nos tubeformers chez SBKJ SPIRAL TUBEFORMER peuvent gérer diverses tailles et épaisseurs de feuilles de métal. Nous avons les meilleures machines qui peuvent traiter la tôle. Ce qui signifie qu'elles peuvent gérer aussi bien le métal fin que l'épais sans aucun problème ! Nos tubeformers vous permettent de produire facilement des tubes ou des conduits dont de nombreuses industries ont besoin. Ces tuyaux et conduits transportent de l'AIR, de l'EAU, etc., d'un point à un autre.

Les gaines sont essentielles pour les flux d'air si vous travaillez dans le domaine du chauffage, de la ventilation et de la climatisation (CVC). Les conduits d'air sont les canalisations par lesquelles l'air chaud ou froid entre dans un bâtiment. Ils doivent être fabriqués avec soin afin de ne pas affecter le flux d'air à l'intérieur de manière fluide et efficace. Si les gaines ne sont pas correctement et précisément construites, cela peut entraîner des problèmes de chaleur ou de refroidissement dans un bâtiment.

Vous pouvez améliorer et faciliter votre travail de canalisation avec un Machine à conduits d'air de SBKJ SPIRAL TUBEFORMER. Avec nos machines, vous êtes capable de fabriquer des conduits correctement formés et dimensionnés à chaque fois. Cela signifie moins de temps passé à corriger les erreurs et plus de temps à accomplir votre travail. Nos tubeformers permettent à vos conduits de s'adapter parfaitement et de fonctionner correctement, rendant ainsi votre travail beaucoup plus facile.

Depuis plus de 20 ans, nous améliorons notre technologie de tubeforming. Elles fonctionnent pratiquement sans problème, et nos machines sont conçues pour être précises et rapides afin de fournir de bons résultats à chaque fois. Pour être précis, cela signifie que nos machines sont capables de fabriquer des conduits et tubes qui s'adaptent parfaitement à la forme et à la taille souhaitées. Cela est critique pour s'assurer que les pièces s'emboîtent bien ensemble.

Nous fournissons également des machines qui sont faciles à utiliser. Elles sont équipées de commandes simples pour changer les paramètres, si nécessaire. Ainsi, vous pouvez apprendre rapidement à les utiliser, même si c'est la première fois que vous utilisez un tubeformer. Étant automatisées, vous pouvez être sûr que vos tôles métalliques seront déformées correctement et rapidement. En général, cette automatisation vous fait gagner du temps et réduit les erreurs humaines, ce qui peut jouer un grand rôle dans le succès de vos processus commerciaux.

Il n'y a pas si longtemps, il était nécessaire pour les ouvriers de torsader manuellement des feuilles de métal. Tout cela était un travail très dur et prenait beaucoup de temps ! Cependant, en utilisant nos tubeformers, il est beaucoup plus rapide de créer des tubes et des canaux ! Cela signifie que vous disposez de tout l'équipement nécessaire pour produire des produits de haute qualité, sans jamais transpirer.