They are Elbow Formings, specialized workers who manufacture a crucial component in duct systems that buildings use. These workers — in esoteric parlance, they are called elbows, which are angled chunks of steel. Elbows join rays of pipes and tubes in systems that heat, cool and ventilate buildings. These little but mighty components make major contributions to helping make our buildings comfortable and healthy for everyone inside.

Elbow Making is an age-old art. The art of making elbows had been around since metals were first worked with. Elbows were originally individually shaped by hand using hammers and anvils. Today, elbow manufacturers have the help of machines to manufacture how they are widely regarded and with more precision. While the tools have evolved, the skill and artistry required to create elbows are still critical.

Few are called to the vocation of elbow making. It takes thousands of hours of training and practice over many years. Those who are experienced in the craft will say it begins with learning how to manipulate various metals like steel, aluminum and copper. All metals have their own properties, and the makes of elbows need to know how to treat each metal correctly. They also learn to operate and maintain the machines that bend the metal into elbows.

Once they master the base skills, 1602 forming heads can then design their own custom shapes. This creative process is fun and takes much skill and attention to detail. Each elbow has to be manufactured to the exact specifications, meaning it has to fit precisely into the duct work. A wrong fit of an elbow can create trouble in heating and cooling systems of a building.

Elbow makers are real artists and have a lot of different skills. They should be able to identify the different kinds of metal, and how to safely and properly work with each one. They also must read blueprints, which show in detail how the elbows are to be made. It is crucial to follow these instructions at both factories very carefully to ensure each elbow is made correctly.

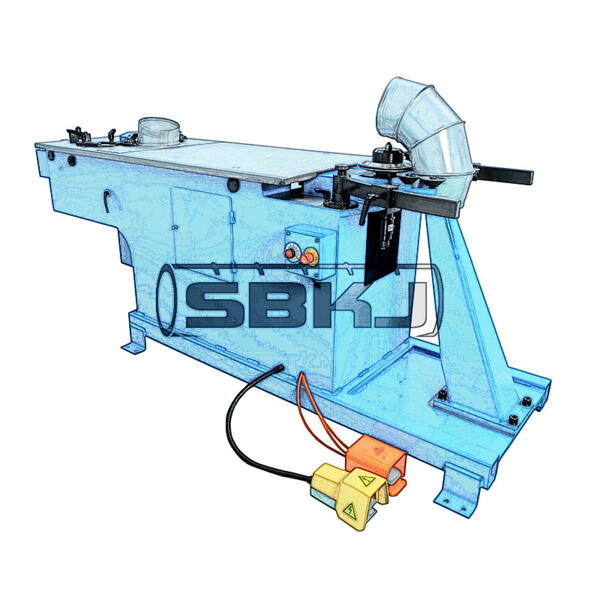

In addition, the elbow makers themselves have to work the machines that are used to manufacture these vital components. They’re trained to troubleshoot problems that may arise with the machines. It is harmless to look after the systems and made that production process performed for making certain that the elbow shape is ready on time.

Although gut makers are working with technical tools and machines, they also have a creative side. They focus on producing unique designs that both serve a purpose and are visually appealing. Depending on the needs of your project, elbows can be many shapes or sizes. This malleability enables elbow makers to create exactly what is needed for each job.