What is Welding, and Why is it Important? When you think about welding, you are thinking about the process of combining materials to create something stronger. There are several different types of welding methods, but one of the most precious methods is you can use Laser Cutting Machine. This unique type of welder uses lasers to join materials, and it offers several advantages over conventional welding, which humans have employed for centuries.

For example, one major advantage of a laser seam welder is that it operates significantly faster compared to other welding techniques. In ordinary welding, a lot of energy is consumed in heating up the materials for joining and so is a time taking process. It takes a lot of time and a lot of work. But with a laser seam welder, it is faster and more accurate. The laser heats the materials extremely quickly and bonds them cleanly, minimizing process time. This rapid-fire process aids manufacturers in getting products out faster, which is good for businessQ Smaller environmental footprint: Less material is consumed during the welding, thus reducing waste.

Another advantage of 1602 forming head is that it creates welds with strong joints and no visible seams. Traditional welding techniques tend to create lines or joints that can create a weaker point in the material. These seams make the end product less visually descriptive as well. But with a laser seam welder, the bond is so tight that you can’t necessarily tell where the materials connected. These processes further strengthen the materials and promote durability. This creates a product that not only is stronger but looks better, which is important to many people and businesses.

For these reasons, welding thin materials can be difficult; it takes precise heat and pressure to sufficiently bond them together. If the heat is too intense, however, the thin materials can warp or become damaged. Laser seam welder is ideal for thin materials. Because the laser generates highly concentrated heat it can easily and cleanly weld even the thinnest materials. This thin materials working brings both durable and strong products for manufacturers without worrying about ruining joined pieces.

The ability to control the welding process with a laser seam welder is another major benefit. You can vary the laser to give exactly the right amount of heat and pressure to make a perfect weld. That means that the final product appears very clean, without seams or joints. Not only does a smooth finish make the product look better, but it also makes it more durable. A better-made product can withstand more stress and last longer, which is good for both the manufacturer and the customer.

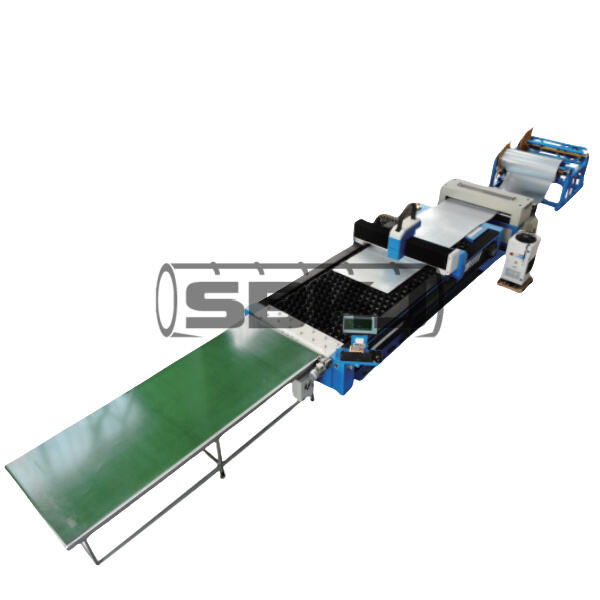

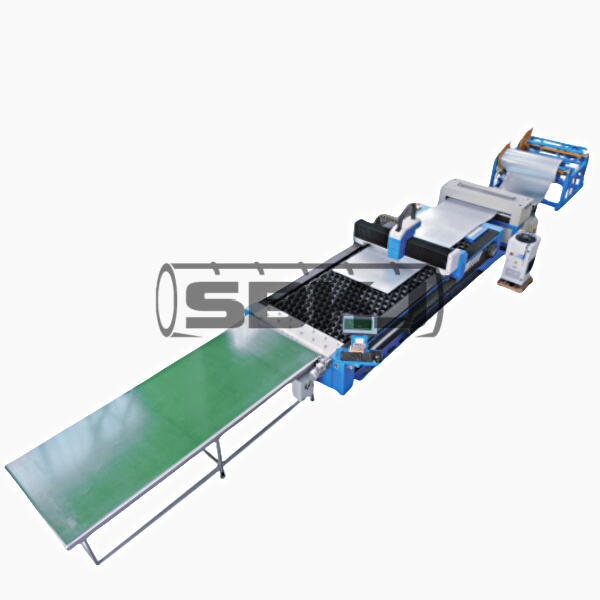

SBKJ SPIRAL TUBEFORMER has various types of laser seam welders that can be used for many welding works. Energy-efficient and user-friendly welders high quality. It means you are able to produce high-quality products without hassle. With our laser seam welders, you get robust welding, rapid joining, and excellent control. Whether it is thin sheet material or thicker, can make your job easier by being able to do a terrific job with our welders.

SBKJ Group is based in the Yangtze River Delta, near Shanghai, China. SBKJ has over 30 years of experience producing spiral tubeformers from 1995. SBKJ has gotten the certificates of laser seam welder and CE. SBKJ spiral tubeformer can meet the standards of DIN, BS, Euroorm and Smacna. Our customers are from over 60 countries around the world.

laser seam welder provides OEM services. You can opt to eliminate the SBKJ logo from your device or request a customised color for the device. The language that the software uses can be set in the event that you provide translations for languages that are not major. We can also customize the equipment you need according to your production requirements

SBKJ is laser seam welder as the most renowned and leading manufacturer of spiral ducts with several patented inventions, like the Flying silitter and Flying crinnper. SBKJ's research and development efforts are the basis of our automatic tubeformers, which produce top quality ducts at lower costs.

We have a dedicated customer service laser seam welder for each customer in addition to a fixed After-Sales Service Hotline and an after-sales WeChat Group dedicated to the after-sales. We are easily accessible on the internet. By relying on the Internet as well, we can promptly assist you and assist you in solving problems. SBKJ's equipment is covered by 1 year warranty and lifelong paid maintenance.