Laser welding is a process involving fusion between the two parts, which uses a laser to bind very thin layers of solid material together. A laser is an extremely intense beam of light that can be directed and focused on a point on the metal. The beam of laser upon hitting the metal, heats up at very high temperature and makes its surface melt. Think about how ice cream melts when taken outdoors on a hot day! Once cooled, the molten metal solidified, bonding the two pieces of metal securely onto one another. The process aids in developing durable, permanent joins for metals.

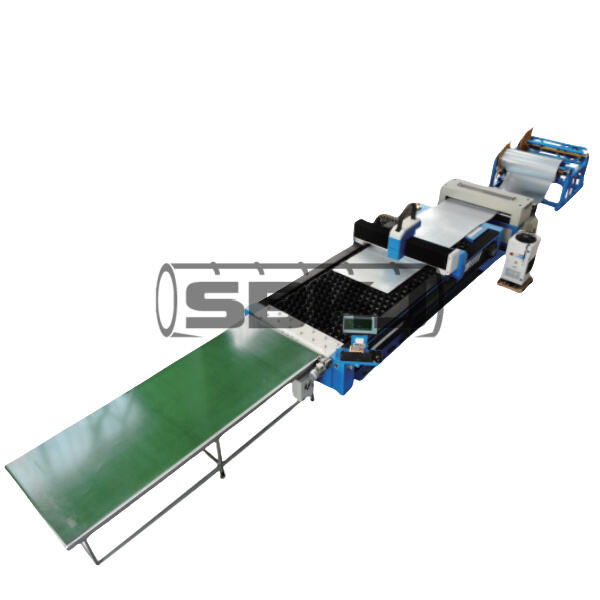

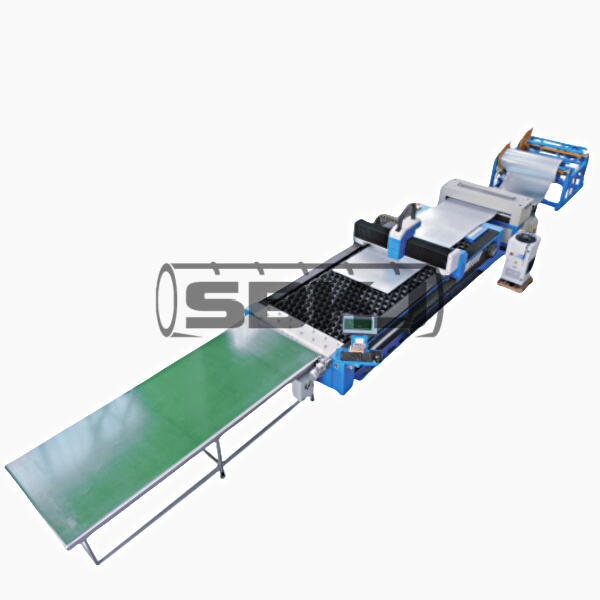

Laser welding revolutionizes the work of factories to a LARGE EXTENT! They used to do this by welding a torch and flame. This approach can be risky and was rather inexact, which meant that getting the weld just right wasn’t easy. Now, factories using 1602 forming head can be far more precise — and can therefore create much stronger joins between bits of metal. This leads to better products and also allows factories to produce faster and more efficiently. So, many factories are adopting laser welding in their manufacturing process.

Laser welding: A great option for small projects! It is extremely fine, allowing it to piece even the smallest of components without error. This is useful for making tiny machinery or toy components. Furthermore, laser welding is fast and does not waste materials, which means even small projects can be completed in a short amount of time and with minimal waste. But it is a smart way to work on small projects and it certainly helps people save money and time.

Need to know about laser welding (if you want to go learn, want to know) Laser welding well takes a lot of practice and skill, first. Only trained professionals who know what they are doing can use a laser welder. Another point is that laser welding machines tend to be very costly, and thus, not every company can afford them. Last but not the least, even though laser welding is the best solution for countless projects, it is not necessarily the right solution to every application. This way may not be the best option for your needs, so consider what you need before going this route.

Laser welding, for major projects, is a true friend. It is extremely rapid, enabling a high volume of products to be produced in a short time and allowing businesses to meet demand. In addition to being precise, laser welding creates large products with little waste. Which is really good because it saves materials and money. In addition, laser welding produces strong and durable products. That means when purchasing a laser welding manufactured item, it will still be in good shape long after you have purchased.